Free cooling systems

Free cooling systems

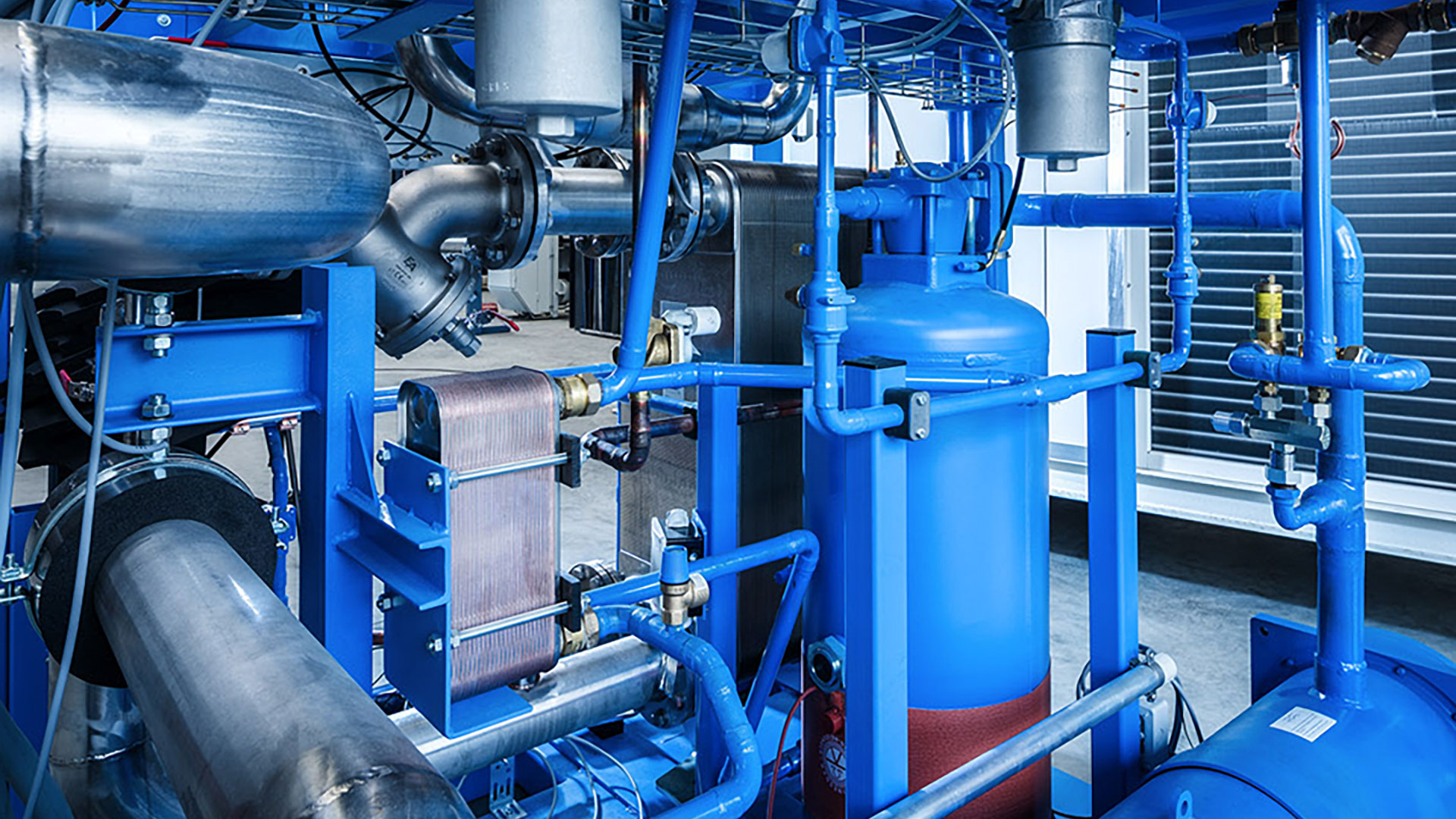

L&R free cooling systems are manufactured as cooling systems for outdoor installation. The pump-tank unit for the free cooling unit is installed indoors.

We produce these systems with cooling capacities of up to 1,000 kW, which can be expanded by modules. Free cooling systems (“winter relief”) are produced as glycol recirculating chillers with a frost-proof water-glycol mixture, or as self-draining free cooling units for operation with pure water.

With this patented method, the free cooling unit is designed and equipped with safety devices to prevent freezing. The system is constructed according to the customer’s requirements.

Do you need advice or do you have a question? Just send us an

Numerous options

Free cooling systems

WATER TREATMENT

Depending on the water quality and operating conditions, the use of special water additives is necessary to prevent deposits, corrosion and contamination. Corrosion inhibitors are added to keep corrosion rates low. The range on offer takes into account the materials, water quality and operating conditions. Combination products with a cleaning effect are often used to keep surfaces clean at the same time. Hardness stabilisers and dispersants can prevent new deposits and remove existing ones. In this case, having the appropriate filter technology is a prerequisite. The correct dosage is provided by quantity-controlled dosing pumps, depending on the level of water consumption. The use of broad-spectrum biocides is necessary to prevent system germination. Germs can attack materials, clog heat exchangers with slime and change the water quality. Regular doses prevent this.

EC Fans

Nowadays, highly efficient EC motors on the fans around the condenser should be speed-controlled, which means they are controlled according to demand and represent part of the energy efficiency of an overall system.

MHP – HYDROPHYSICAL WATER TREATMENT

Protects the system against impurities and blockages in the heat exchanger channels.

Reduces deposits of biological matter.

Stainless steel strainer basket filters with bypass for cleaning during operation.

PUMP-TANK SYSTEM

Avoid harmful, short compressor running times in chillers by using a sufficiently large tank.

Partition walls serve to avoid mixing temperatures.

Stable temperatures due to large buffer tanks.

Optimum output conditions for pumps.

Flexible retrofitting of pumps and water technology.

SAND FILTER

Removal of solids is important for high

operational safety and proper water quality.

All larger particles (200 µm) in the main stream are removed with a sieve cloth to protect plant components.

Monitoring and a bypass circuit are important here. In a separate side stream, on the other hand, even the finest solids (5 µm) should be continuously removed, e.g. with a filter cartridge or a sand filter. Otherwise, this could lead to silting or deterioration of water additives. Depending on the design, automatic cleaning of the filter by backwashing is possible.

Drilling

Piping must be of sufficient dimensions to prevent losses.

Minimum pressure rating of 16 bars.

Optimum flexibility and clarity.

Various materials for the respective application (CU, SS, PVC, PP, PE).

Optimum insulation to avoid temperature fluctuations.

SOFTENING

If the make-up water contains too much lime, or lime deposits are to be expected due to the operating conditions (high temperatures, evaporation), softening of the make-up water is necessary. Occasionally, under particularly critical conditions, complete desalination of the make-up water is required.

To soften the make-up water, ion exchangers are used, which exchange the calcium and magnesium ions that form deposits for sodium ions. If the exchange capacity is exhausted, the ion exchanger is regenerated with a saline solution and becomes available again. The regeneration process is fully automatic.

With softened water, lime scale deposits can no longer occur. Softened water cannot build up natural corrosion protection due to its lack of hardness; depending on the material, the use of a corrosion protection agent is then required.

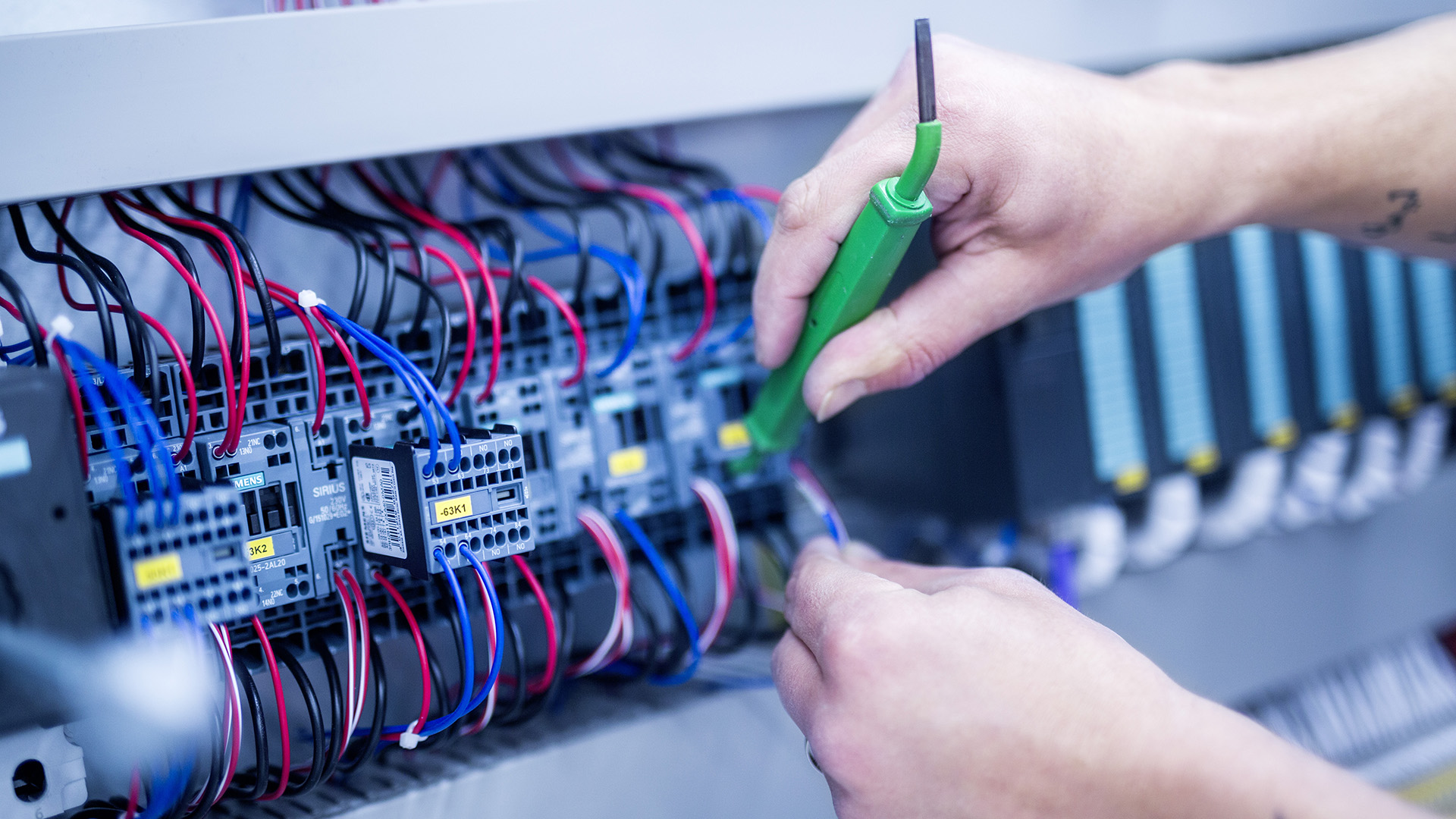

PUMPS

The consumer pumps on our refrigeration systems are equipped with pressure-dependent, speed-controlled drives. This reduces the energy consumption of the pumps by up to 40%.

Pumps from the L&R ECOPRO efficiency range are also speed-controlled and, in the case of the KSB pump, are equipped with SuPremE drives. The combination of synchronous reluctance motors and frequency converters allows high energy savings, especially during partial load operation.

FILTER TECHNOLOGY

Stainless steel strainer basket filters with bypass for cleaning during operation.

Protects the system against impurities and blockages in the heat exchanger channels. Reduces deposits of biological matter.

Your contact partner for

Free cooling systems made in Germany

THOMAS IMENKÄMPER

Management (CSO)

Phone +49 2935 965-20

t.imenkaemper@lr-kaelte.de

Postcode areas (Germany) 01-04, 06-10, 12-19, 32, 33, 39-42, 44-49, 58, 59, 95, 96, 98-99

GEORG HESSE

SALES

Phone +49 2935 9652-203

g.hesse@lr-kaelte.de

Postcode areas (Germany) 34-36, 50-56, 60, 63-69, 97

MICHAEL FRYE

SALES

Phone +49 2935 9652-209

m.frye@lr-kaelte.de

Postcode areas (Germany) 20-31, 37, 38, 49