BIOCIDE-FREE AND ECONOMICAL

BIOCIDE-FREE AND ECONOMICAL

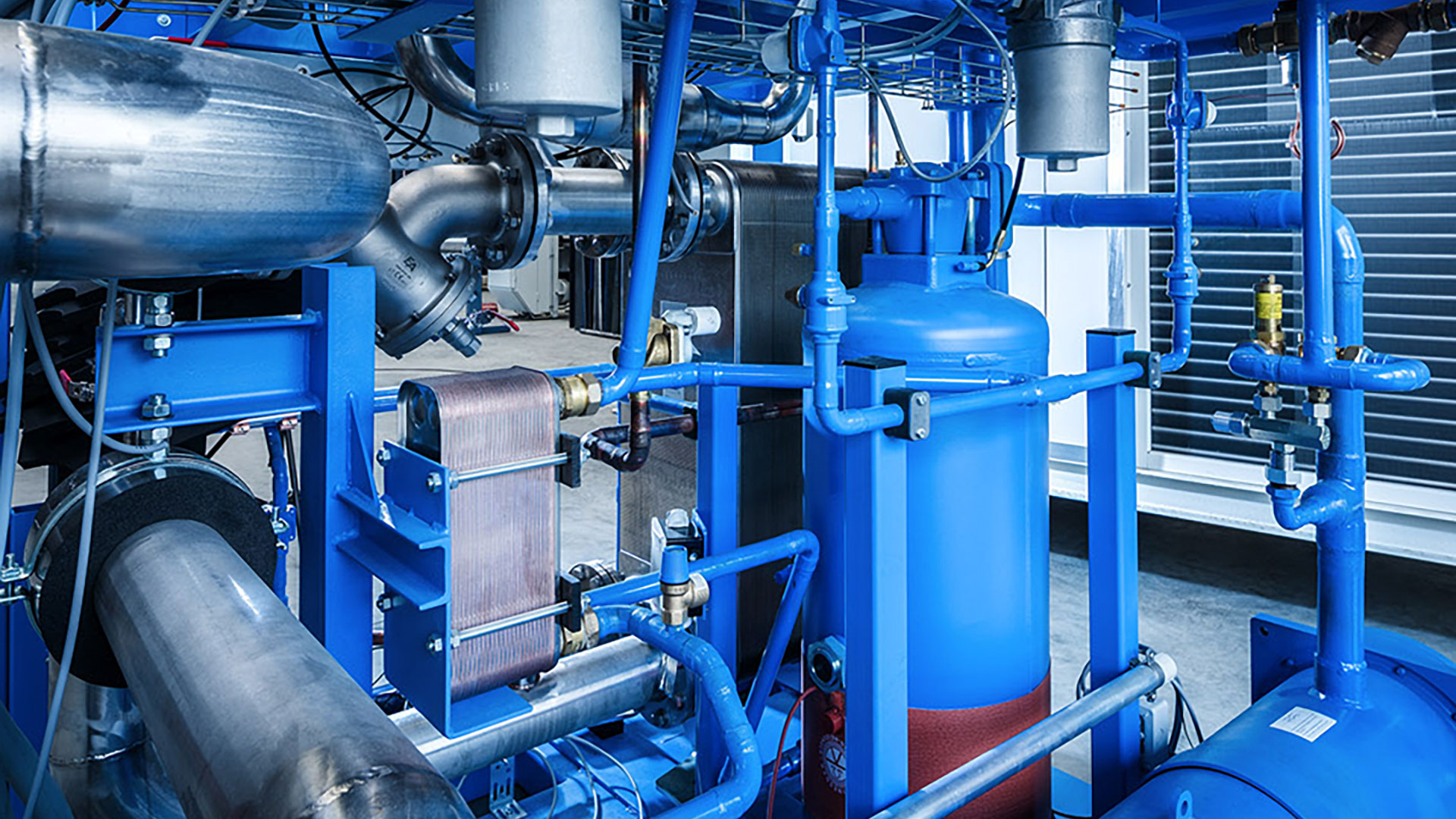

The core component of an MHP system is a reaction vessel whose internal structure is similar to that of a cyclone. A pressure pump increases the water inlet pressure to approx. 5 bar and conveys the water to be treated into this reaction chamber, which generates extremely high centrifugal and centripetal forces. In addition, high shear and friction forces as well as negative pressure and cavitation develop.

The combination of these very high physical forces literally rips open and destroys bacteria and other contaminants with complex molecular structures. What remains are bacterial fragments, which are eliminated through cold oxidation. This cold oxidation takes place as a parallel process.

As recommended by VDI guideline 2047 (“Hygiene in re-cooling plants”), the impurities rendered harmless in this way can be separated from the circuit e.g. via existing filter systems or those supplied with the MHP system.

With these properties, the MHP system is very well suited to keeping circulating water in cooling towers hygienically stable and minimising infestation with legionella and other microorganisms.

The process can be used in evaporative cooling systems as well as in hybrid, wet or natural draft cooling towers. It works sustainably, because it prevents recontamination, so the water remains hygienically stable in the long term. Since it has no mechanical moving parts, wear and tear on the system is low and there are no costs for chemicals (biocides).

Another advantage is that the formation of insulating biofilm layers and biologically induced incrustations on pipe registers and heat exchangers is prevented, thus maintaining their efficiency.

L&R uses the method both when designing new plants with open cooling towers and when retrofitting existing plants. The MHP process is very suitable for this purpose, because it can be easily integrated into existing (re)cooling systems as a bypass solution.

As a basic programme, L&R customers can choose from system sizes for capacities of 1 to 51 m3/h. For on-site customer tests, L&R has a mobile rental unit available.

Your contact partner for H₂O technology –

natural water treatment

GREGOR HEIERMANN

WATER TREATMENT SYSTEMS SALES

Phone +49 2935 9652-210

g.heiermann@lr-kaelte.de