Energy-saving refrigeration system for shiny surfaces on automotive trim parts

A leading automotive supplier from the Sauerland region has commissioned an 80-metre-long anodising plant for perfect surface treatment of trims and decorative strips. A refrigeration system from L&R Kältetechnik ensures that the electroplating baths are always cooled precisely and constantly – and with the lowest possible energy requirements.

Shine is “in vogue”: This becomes immediately evident when you look at a new car model to see what its radiator and trim panels look like, and how many trim parts enhance the sheet metal. Companies specialising in this field are benefiting from this development. Continued demand for anodised parts led a German automotive supplier to commission a new anodising plant in February 2013.

Filigree anodised parts of the highest quality

The 80-metre-long plant is suitable for surface treatment of filigree components for exterior cladding, such as roof and window trim strips, window guides and roof rails. These parts can be produced with high-gloss, satin or black surfaces in the precise manner that car manufacturers and car buyers desire. And because the automotive supplier supplies premium manufacturers, such as Daimler, BMW and Audi, the plant produces only top-quality parts that permanently retain their perfect surface.

No anodising without cold

It is well known that automotive suppliers are under high cost pressure. Therefore, in addition to the quality and finish of the parts, the operating costs were also a key issue in planning and awarding the contract. This is where refrigeration technology comes into focus: The electroplating baths must be cooled precisely and continuously.

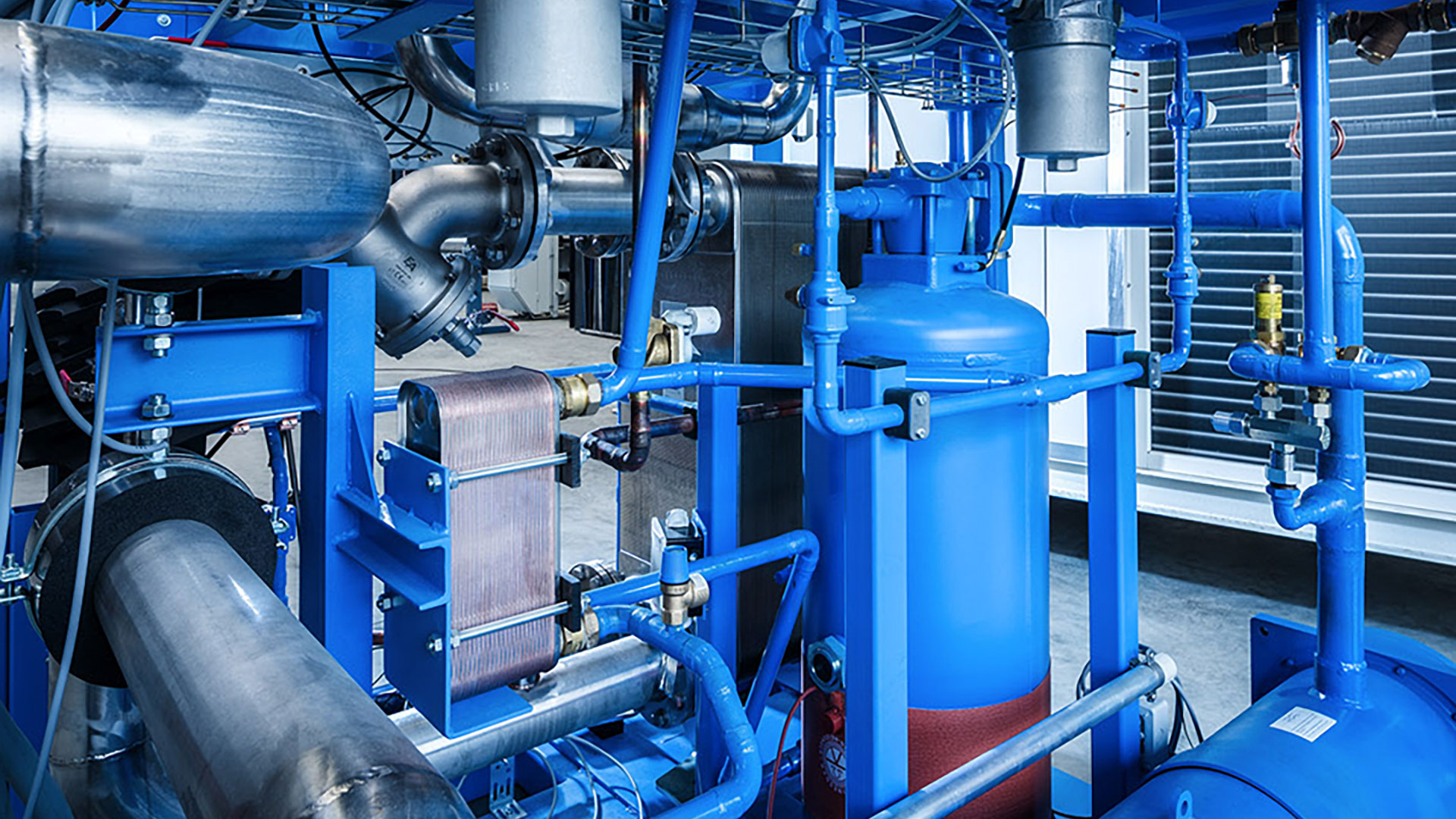

To design and plan the refrigeration technology, the supplier of the electroplating plant worked closely with L&R Kältetechnik GmbH & Co. in Sundern, which has experience from numerous surface technology projects and also pays great attention to energy consumption. Additional challenges were the extreme specifications relating to noise emissions and the very tight space conditions.

For the different anodising baths, two cooling water circuits are required, one with a 12 °C cooling water supply, the other with a 25 °C supply. &R recommended an energy-efficient, water-cooled chiller with a 300 kW re-cooling capacity for the 12 °C circuit. The 25 °C circuit is cooled by a cooling tower system with a total re-cooling capacity of 2,900 kW. The cooling tower system also cools the condenser for the chillers, which also reduces the energy demand on the overall system.

Comprehensive measures to increase energy efficiency

Other energy-saving measures implemented by L&R include the use of speed-controlled pumps in those circuits where varying flow rates are to be expected. “Winter relief” (free cooling) optionally relieves the chiller whenever the outside temperature is lower than the return temperature of the cooling medium. This means: At temperatures below 19 °C, “winter relief” switches on and reduces the energy requirement of the refrigeration system. At an outdoor temperature of 7 °C, the entire cooling requirement of the chiller can be provided by free cooling. No other process for producing cold water requires so little energy. Since the investment is manageable, this option usually pays for itself very quickly.

Project planning, construction and commissioning in a short time

Just the design and characteristics of the system, which has a “COP” (coefficient of performance) of 4.34 at a condensing temperature of 47 °C, demonstrate the efficiency of this refrigeration technology concept. The operator attached great importance to this in order to keep operating costs as low as possible, even if energy prices continue to rise in the future.

The energy savings resulting from this innovative refrigeration technology cannot yet be quantified, because the system was only commissioned a few weeks ago. It is also worth mentioning that the refrigeration system and the

pump-tank system have been installed in a very compact space and are characterised by very low noise emissions. Moreover, it was planned and put into operation in a very short period of time. Once the operator had given the go-ahead for the investment, the company wanted to make use of the new anodising plant as quickly as possible and to increase its capacity for “Class A” surface quality trims and panels.

Sector

Surface & electroplating technology

System solution

Water-cooled chillers